Tips for Developing a Food Processing Plant

Working in the food industry, you know the importance of food processing plants. They create and package much of the food we eat and rely on each day. If you are opening a food processing plant or looking to revamp your current operations, there are plenty of ways to go about it. Here are the best tips for developing a food processing plant.

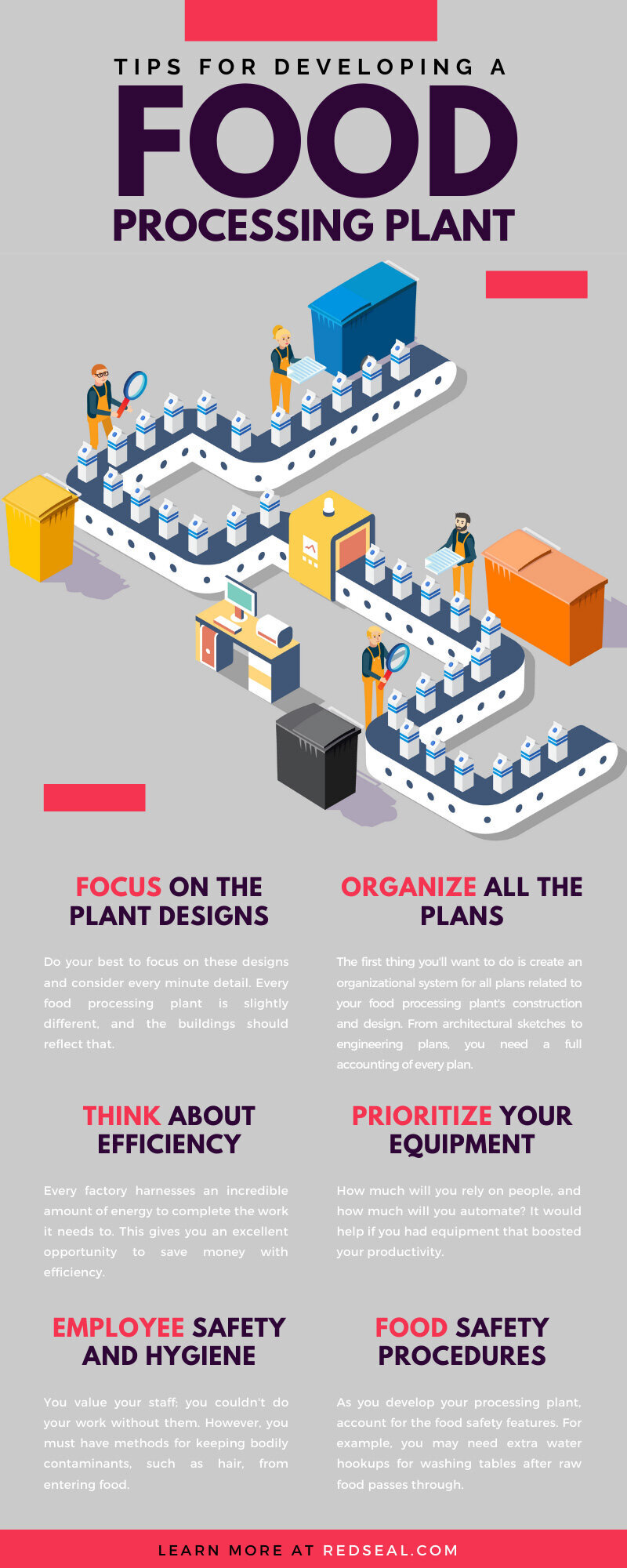

Focus on the Plant Designs

Once you decide on a location, there are dozens of design aspects to consider. This leads to a myriad of paperwork and plans for your facility. Do your best to focus on these designs and consider every minute detail. Every food processing plant is slightly different, and the buildings should reflect that.

Organize All the Plans

The first thing you'll want to do is create an organizational system for all plans related to your food processing plant's construction and design. From architectural sketches to engineering plans, you need a full accounting of every plan. Whether you use a filing cabinet or a cloud-based data management system, you must be able to find every workup and layout at a moment's notice. During construction, specific questions may arise which you can only address with the original plans. Or, if you find structural problems, you'll need an accurate blueprint to find a solution. Organization is key.

Imagine the Entire Process

When you craft food plant designs, keep the entire process in mind. From material delivery to product distribution, you should imagine each step of the food processing journey and ensure you have the appropriate space and equipment for each step. In doing so, you can craft a workflow from station to station and allocate the area for each place. When you have an accurate vision of the whole procedure, you can make informed decisions about building your facility or how you use the space inside your current building.

Think About Efficiency

Every factory harnesses an incredible amount of energy to complete the work it needs to. This gives you an excellent opportunity to save money with efficiency. Energy-saving machines and water-efficient processes can reduce utility costs. With a conservationist mindset, you can mitigate wasteful habits that end up costing you thousands of dollars each year. It would also help if you also concerned yourself with time efficiency. Your products should move from station to station in a logical path that reduces transport times. All these considerations impact your plant design and how you organize the interior.

Prioritize Your Equipment

When you design your food processing plant, you must prioritize your equipment. How much will you rely on people, and how much will you automate? It would help if you had equipment that boosted your productivity. You could opt for the minimum option to save money, but this could cause future problems. Ensure you meet industry standards and have highly rated equipment—but remember, select items that will last. You should also set schedules for preventive maintenance to address broken parts. If you need high-quality flexply replacement parts for your machines, check out our wide selection at Red Seal Electric Company.

Your equipment is an investment, so treat it as such. You should consider equipment management systems that can integrate all your machinery. Many machines can connect to a central software from which you can monitor and evaluate the work.

Consider Your Health and Safety Standards

Health and safety are two sides of the same coin, especially when it comes to your staff and your product. Consider the standards you set in place for your plant to ensure a productive and secure environment.

Employee Safety and Hygiene

You value your staff; you couldn't do your work without them. However, you must have methods for keeping bodily contaminants, such as hair, from entering food. For example, you can implement hair net protocols and clear glass shields to protect your food products from your workers. You should also have a worker sanitation area where staff can clean off before they enter their station.

Employee safety standards also go the other way. You should have methods for keeping staff safe from your food products and heavy machinery. Whether they’re processing raw meats or operating forklifts, you should give them in-depth safety training. It’s also best to consider cleaning practices in the early stages, as it may impact plant design. For example, you should think about non-slip flooring materials and the location of flood drains. With these food handling and employee safety protocols in place, you can keep everyone safe.

Food Safety Procedures

In food processing, you need the precision that only orderly procedures can provide. Otherwise, a malfunctioning machine or uninformed employee could wreak havoc and destruction. As you develop your processing plant, account for the food safety features. For example, you may need extra water hookups for washing tables after raw food passes through. Or, you may need extra supply closets in each room for masks, gloves, and cleaning chemicals to ensure the food is safe. Be sure to check any and all mandates for food safety so your facility passes every inspection.

The Surrounding Environment

Every industrial plant exists in a community on physical land. This means others are living around the factory and have a larger ecosystem to keep in mind. When you develop your food processing plant, consider disposal and waste management. Not only does this keep your local community safe, but it also protects your product and your staff from disease. When you do everything in your power to reduce contamination risks, you can honestly affirm your commitment to a sustainable and healthy operation—not to mention the positive public relations with locals.

Take these tips for developing a food processing plant into account as you build or renovate your space. Your investors and superiors want an industrial facility that proves its worth, so take the time to deeply ponder each step of the process. With the right mix of intentionality, research, and innovation, you can create something that’s truly one of a kind.