Image 1 of

Image 1 of

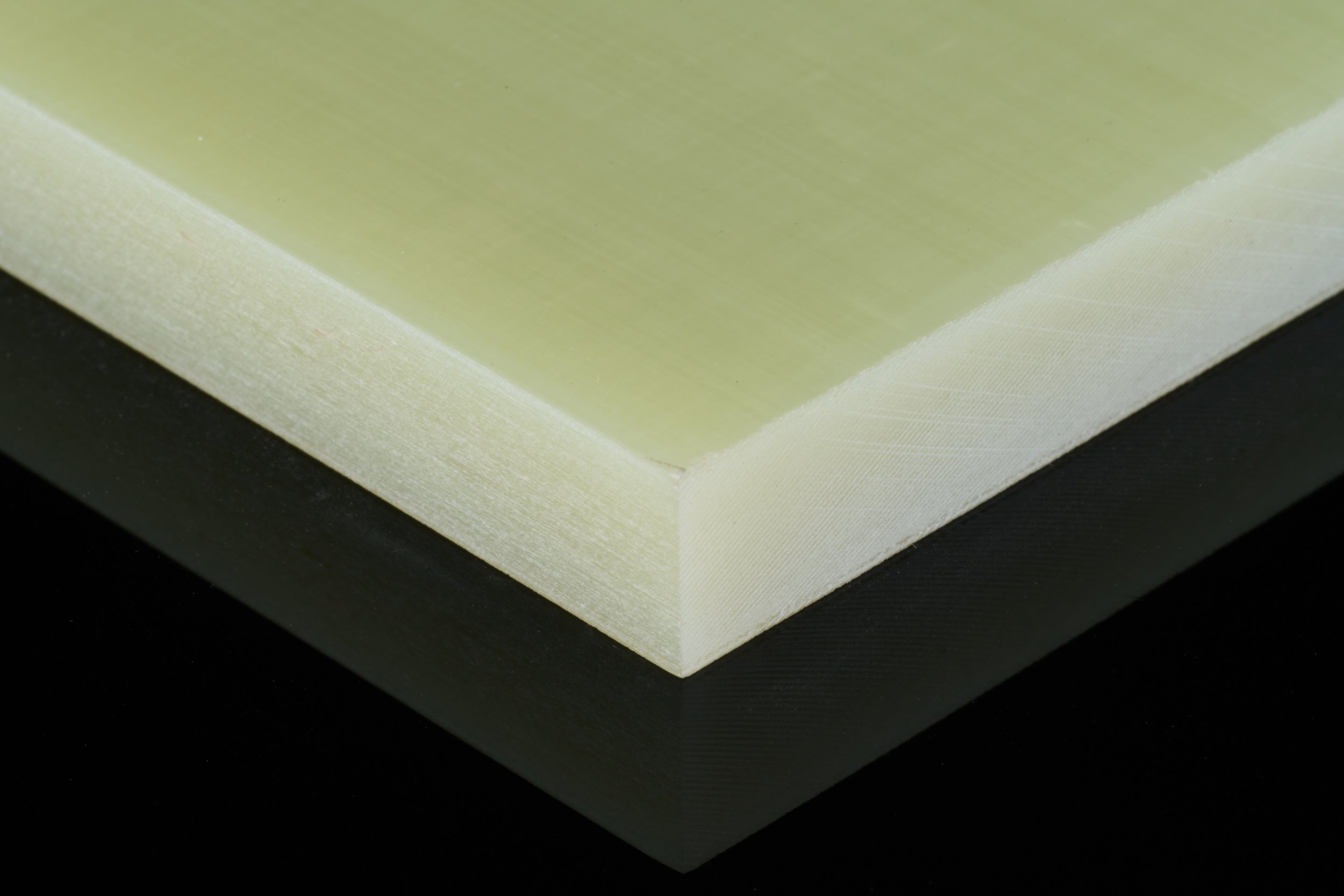

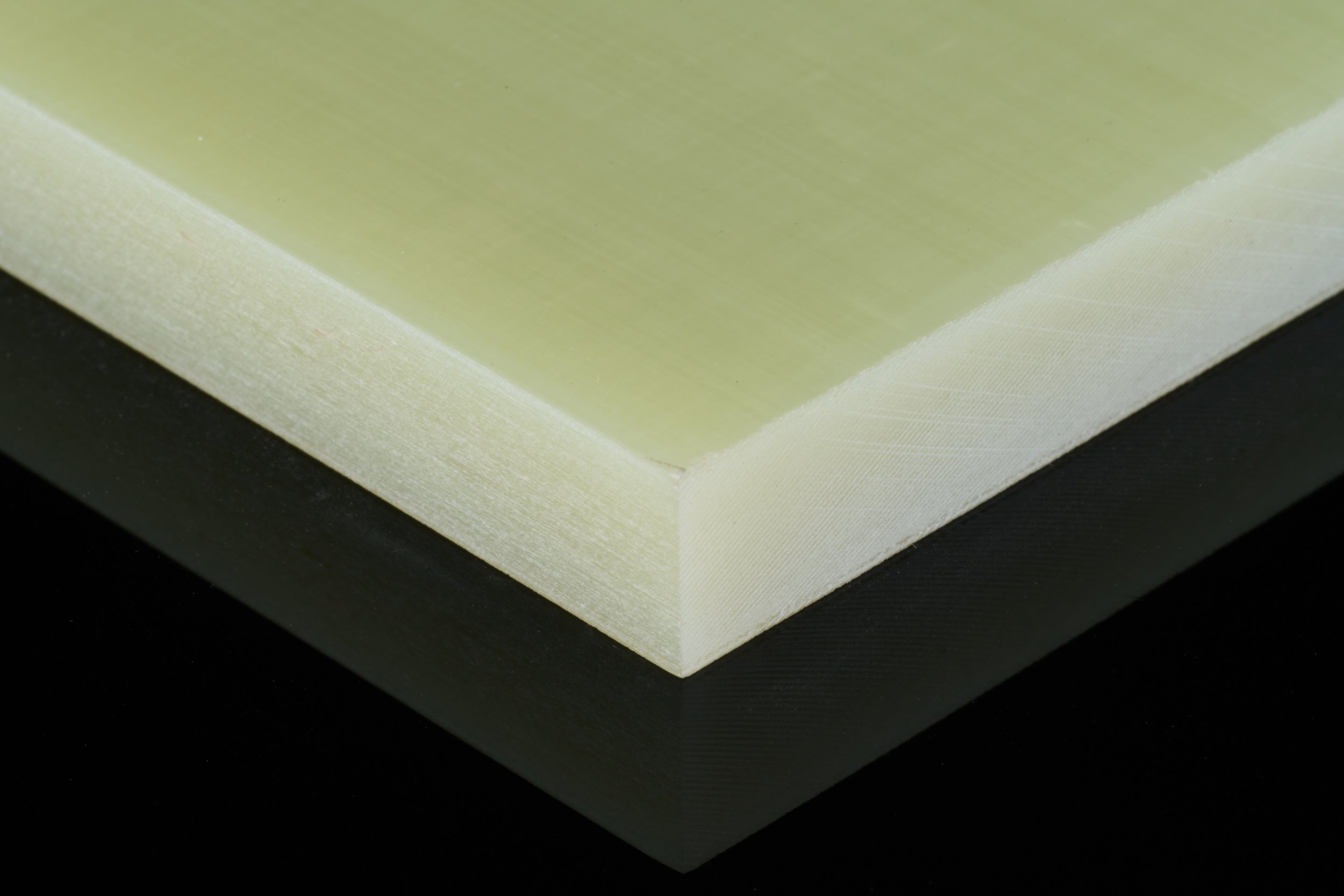

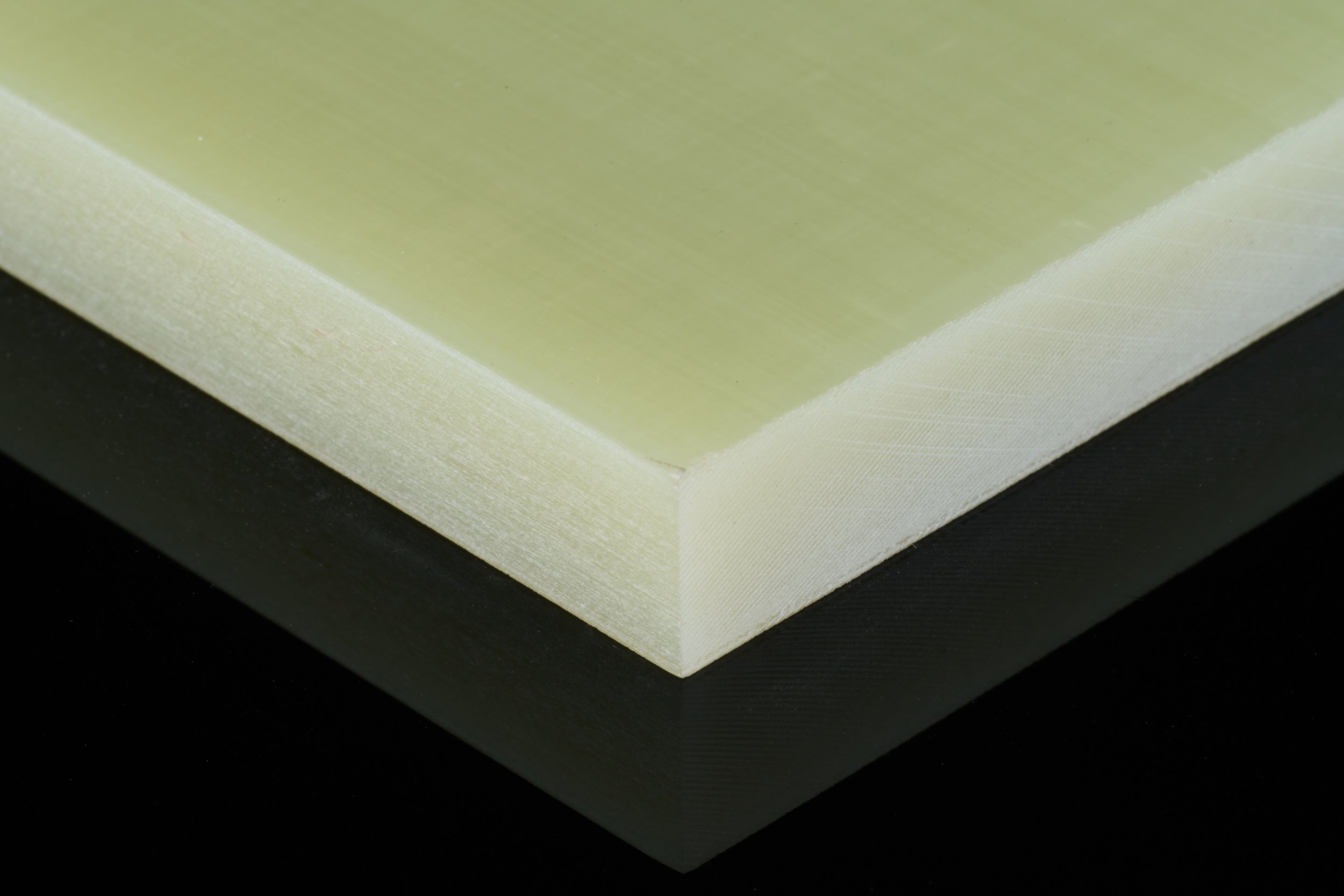

FlexPly® Composite Springs

Our supplier, Composiflex, designs and manufactures a variety of E-glass/epoxy, carbon/epoxy, and high-temperature glass/epoxy FlexPLY® composite springs for numerous industrial equipment applications. These flat springs are most commonly employed within the drive systems of vibratory equipment where they are loaded in bending and excited at their natural frequency.

Our supplier, Composiflex, designs and manufactures a variety of E-glass/epoxy, carbon/epoxy, and high-temperature glass/epoxy FlexPLY® composite springs for numerous industrial equipment applications. These flat springs are most commonly employed within the drive systems of vibratory equipment where they are loaded in bending and excited at their natural frequency.

Our supplier, Composiflex, designs and manufactures a variety of E-glass/epoxy, carbon/epoxy, and high-temperature glass/epoxy FlexPLY® composite springs for numerous industrial equipment applications. These flat springs are most commonly employed within the drive systems of vibratory equipment where they are loaded in bending and excited at their natural frequency.

FlexPly® Composite Springs come in a wide range of thicknesses ( plies) and in both Cross Ply and Unidirectional Ply layups. We would be happy to supply samples for testing in your application. Designed and manufactured by Composiflex, they offer a variety of carbon/epoxy, E-glass epoxy, and high-temperature glass/epoxy springs for industrial equipment uses. These flat springs are most commonly employed within the drive systems of vibratory equipment where they are loaded in bending and excited at their natural frequency. Some examples of these types of machinery include conveyors, oscillating sanders, vibratory rollers, vibratory feeders, and more.

These composite springs are an excellent replacement for steel springs. They provide various advantages, which include:

Industry-leading solutions

Elongated fatigue life

Tensile strength

High strength-to-weight ratio

Noise dampening

Variable modulus of elasticity

Scratch resistance

Low notch sensitivity

Customizable forms

Chemical and corrosion resistant

Consistent spring rate

Varying thickness options

FlexPly has been shown to perform exceptionally well in high-stress and start/stop conditions. Additionally, this composite material is capable of handling temperatures reaching 300 degrees Fahrenheit for short periods of time. These springs will maintain their integrity even under these high-temperature conditions.

Spring stiffness is a crucial design factor in any vibrating system. FlexPly is designed to outperform, outlast, and provide overall better consistency when compared to various types of other composites. The lifecycle alone makes this the preferred choice for extreme vibratory conditions.

Extensive “on-demand” inventory.

Can be supplied as blanks or fabricated parts.

We can save you time and money by providing custom springs to you on a Just in TIme basis.

FlexPly Product Downloads: