Custom Fabrication Services

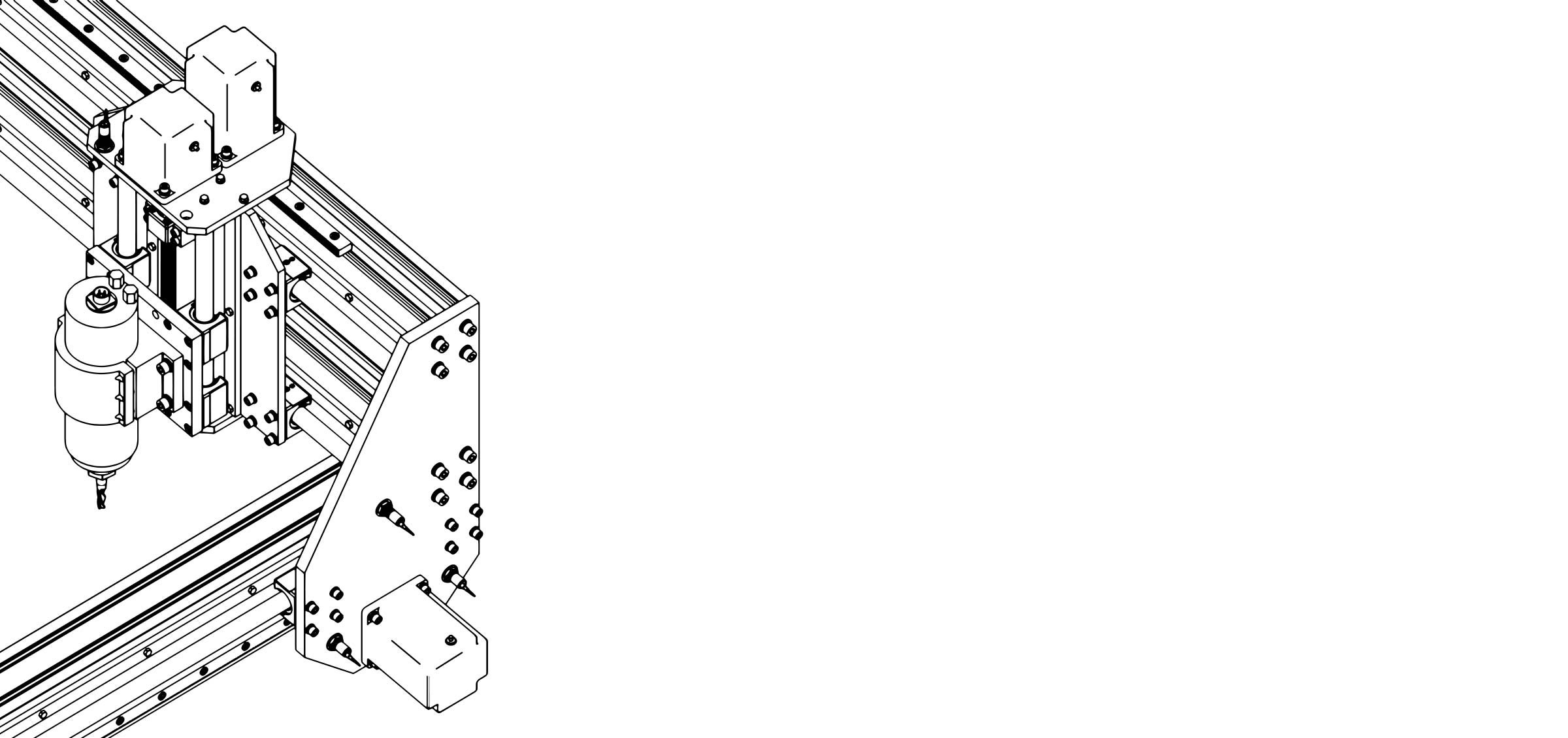

Innovative Part Machining

Fabricating composite insulating materials is entirely different than working with metal. At Red Seal, we’ve been machining composites for decades. We have the experience. We have the equipment. And, most importantly, we have the people to get the job done right — and on time.

Sawing - CNC panel saws - up to 3 inches thick x 10 ft long

Milling - CNC machining centers - up to 4 inches thick x 4 ft x 10 ft

Turning - CNC turning - up to 8 inches diameter x 24 inches long

Stamping & Die Cutting - Available for large or small lot sizes on a variety of materials

Custom inkjet numbering on finished parts

Custom labeling / packaging

Lot control capabilities

CMM inspection and reporting

Fabrication Samples

Featured Fabricated Materials & Products

Inspection Services

Before your product goes out, we perform close inspections and assembly to ensure we meet the precise qualifications for your project. Our computer coordinate measuring machines (CMM) ensure complete accuracy.

Complete quality control

First article inspection

CMM inspection and reporting

Finishing Services

We’re dedicated to going the extra mile for all our customers who require our custom fabrication services! We offer assembly in-house from mechanical fastening, thermal and chemical bonding, and assembly of customer-supplied parts. We can print, silkscreen, or paint your order to customize it specifically for your project. Red Seal is proud to offer custom packaging and labeling and a precise inventory control system that allows us to maintain a 98% on-time delivery rate!

Assembly - Mechanical fastening, thermal and chemical bonding, and assembly of customer supplied components

Finishing - Ink jet printing- with lot number, date, and/or sequential markings, silkscreening, spray booth and dipping.

Custom Packaging and Labeling - Bar coding, drop shipments

Kanban Programs - Just-in-Time deliveries and inventory control